Precision Machine Shop in Pennsylvania

King Precision Solutions

Tight Tolerance Defense Machining

King Precision Solutions is a second-generation ISO 9001-compliant CNC machine shop that offers full turnkey solutions for customers who demand premium-quality products at competitive prices. Our facility is also ITAR-compliant, showcasing our commitment to strict quality control practices and documentation procedures for any project associated with the defense industry including aerospace and precision electronic manufacturing.

Our full-service precision machine shop in Pennsylvania is equipped to offer tight-tolerance CNC machining, 5-axis machining, Swiss lathe machining, and unparalleled repair and polishing services for tools and dies used by a variety of industries across the country.

Serving the Oil & Gas Sector

Tool & Die Polishing Holding .0002

High pressure components to 100,000 psi

Swiss Machining with an Envelope of .05 - 1.500

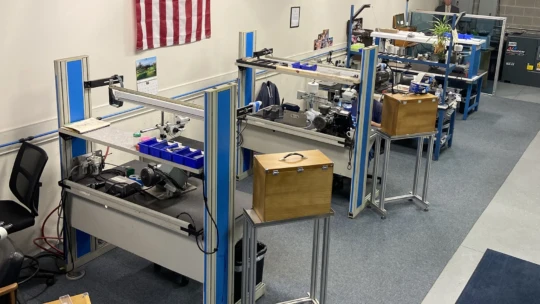

The Machine Shop

Prototype to Production CNC Machining

We have decades of combined experience in CNC machining services and utilize the most advanced available programming software for expedited and efficient production times. At King Precision Solutions, our team machines complex parts for prototyping, production, and fixturing, and offers a variety of additional machining services. These value-added services include surface grinding, CNC 2D/3D milling, and lathes with live tooling with a capacity of manufacturing parts with diameters as large as 12”. Additionally, we are capable of EDM, EDM wire, laser welding, plating, and much more.

The Swiss Shop

Swiss Lathe Machining

King Precision Solutions is an experienced provider of advanced Swiss lathe machining. To find the absolute best machining equipment money could purchase, our team went directly to the source and found the best Swiss lathe machines in Switzerland. Our Tornos GT-26 and GT-32 machines are some of the best automatic turning machines in the world. These incredible machines provide versatile and highly efficient production of complex parts and achieve measurable improvements during production. Through this technology, our team is capable of meeting tolerances as rigid as 0.0002” regularly. We can machine short and long runs depending on your specifications and requirements and excel at overcoming manufacturing challenges.

TOOL & DIE POLISHING

King Precision advanced its tool and die polishing services by adding several industry-best polishers with decades of experience. These first hires are still manning the Polish Shop today and contain the most robust set of knowledge for precision polishing anywhere in the United States. When this intimate familiarity is paired with the best hand tools and microscopes available, and completed within an ultra-modern and climate-controlled facility, customers receive the top-quality tool and die polishing services. We can match D-3 to A-1 SPI mold polishing grades including premier Optical or Diamond Finish to best serve the evolving demands of tool and die shops and injection molders across the country.

ABOUT KING PRECISION SOLUTIONS

King Precision Solutions was founded in Erie, PA in 1990. Since then, we have committed ourselves to excellence, both in the work we do and the way we carry ourselves in our community. We value common sense and ethical principles in our day-to-day business, treating everyone we come in contact with dignity and respect, regardless of race, gender, sexual orientation, color, age, religion, national origin, or disability. Our employees are selected not only for their knowledge and expertise, but also for their character; we look for people who value work and enjoy working with others, who are dedicated and loyal workers, and who bring an enthusiastic attitude to the workplace and carry those same traits and values over to how they interact with our customers.

We are dedicated to continuous improvements and professional craftsmanship, and we actively invest in our people, our plant, and technologies. This is what we do, and the only thing we love more than this work is working with our customers to get them exactly what they need.