Where to Find 5-Axis CNC Machining Services in PA?

Many manufacturers seeking 5-axis CNC machining services in PA struggle to get bids on parts due to their complexity, difficult-to-machine materials, or thin walls. Short lead times and stringent quality expectations only add to the challenge. King Precision Solutions is ready to rise to the opportunity and fully embraces unique part designs with complex geometries that require an experienced touch with state-of-the-art equipment.

Read on to learn where to find the best 5-axis CNC machining services in PA.

What is 5-Axis CNC Machining?

5-Axis CNC Machining is an advanced manufacturing process that uses a computer-controlled machine with five distinct axes of movement. These include three linear axes (X, Y, and Z) for spatial positioning and two rotational axes (A and B) that allow the cutting tool to approach the workpiece from virtually any angle.

This machining method can produce intricate parts with compound curves, undercuts, and detailed features. The technology delivers exceptional precision and can routinely achieve tolerances as tight as ±0.0002 inches, even on complex components.

5-Axis vs. 3-Axis CNC Machining

Traditional 3-axis machining is limited to movement along the X, Y, and Z axes, which limits tool access to only the top and sides of a workpiece. 5-axis machining adds two additional rotational axes, which enable the creation of complex geometries that are otherwise impossible to produce with traditional 3-axis machining.

The advanced approach of 5-axis machining enables superior surface finishes by maintaining optimal cutting conditions throughout the process. It also eliminates workpiece transfers between stations, which reduces the risk of errors.

Why Choose King Precision for 5-Axis CNC Machining in PA?

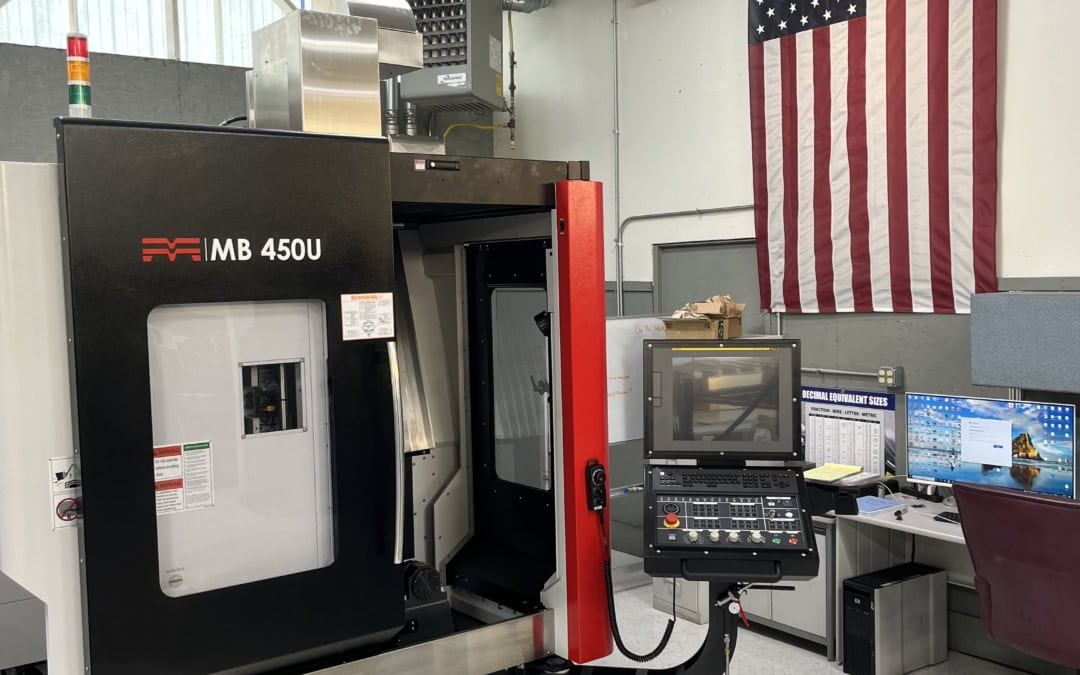

At King Precision Solutions, we specialize in 5-axis CNC Machining Services in Pennsylvania. We leverage decades of industry experience, state-of-the-art technology, and a commitment to delivering exceptional quality parts for high-performance applications at fast turnaround times and competitive prices.

This approach enables our machine shop to utilize the precise and reliable machining procedures needed to solve the toughest manufacturing challenges. Our expertise enables us to bid on projects others find too difficult, particularly those involving complex geometries, difficult-to-machine materials, and components with thin walls.

Our machining capabilities include the following:

- Advanced 5-axis CNC vertical machining capabilities for complex geometries

- Additional specialized equipment, including surface grinding, cylindrical grinding, Ram EDM, and Wire EDM

- We offer advanced machining services with tolerances as precise as ± 0.0002″.

- 12.000″ diameter turning capacity for larger components

- Climate-controlled and meticulously clean manufacturing environment to ensure consistent quality

- Advanced programming software and modern tooling systems for optimal efficiency

- Ability to work with a wide range of materials and customer requirements

- Modernized tooling, work holding systems, and specialized fixtures that streamline production by reducing setup times.

Quality Assurance and Compliance Standards

We maintain rigorous quality control standards that meet the most demanding industry requirements. Our International Traffic in Arms Regulations (ITAR) registration status allows us to handle restricted technical data and manufacture components for defense, aerospace, and military applications. We’re also ISO 9001-Compliant and in the process of becoming a fully certified ISO machine shop.

Our workflow processes integrate quality verification through a coordinate measuring machine (CMM) for precise dimensional inspection. We maintain comprehensive documentation for all manufacturing processes, including material certifications, heat treatment records, and plating verifications. This meticulous approach ensures complete traceability and compliance for our customers in the robotics, aerospace, and defense industries.

Value-Added Services

King Precision Solutions provides many value-added services that enhance the quality and functionality of your components:

Our tool and die polishing services achieve superior surface finishes that extend tool life and improve part quality. Technicians polish parts under microscopes to catch fine details others miss on blocks up to 1,000 pounds. High-power measuring microscopes and calibrated CMM equipment hold important features within .0002″.

Our Swiss lathe machining capabilities include two Tornos CNC Swiss Machines that produce parts with tolerances as tight as ± 0.0002″. We deliver high yields of acceptable and cost-effective parts with low scrap rates. This efficient workflow ensures expedited turnaround times on complex prototypes and full production cycles.

How Does 5-Axis CNC Machining Work?

5-axis CNC machines operate through a sophisticated control system that translates pre-programmed instructions into precise movements. The machine features three linear axes plus two rotational axes, typically involving a tilting table, swiveling cutting head, or trunnion configuration.

These five axes perfectly synchronize to maintain continuous contact between the cutting tool and workpiece at optimal angles. The computer controller calculates thousands of position adjustments per second to ensure smooth tool paths around complex part geometries.

The entire process follows a systematic workflow to transform digital designs into finished parts:

- CAD design – Creates the part’s digital model with all relevant specifications and tolerances defined precisely for manufacturing.

- CAM programming – Translates the design into machine instructions. It determines the optimal cutting paths, speeds, and tooling strategies.

- Setup – Prepares the machine with the appropriate tools, fixtures the material correctly, and establishes reference points.

- Machining – Executes the programmed toolpaths as the machine coordinates all five axes simultaneously to create the finished part.

- Inspection – Verifies dimensional accuracy using precision measurement equipment such as a CMM to ensure the part meets all specifications.

Industries Requiring 5-Axis CNC Machining in PA

King Precision Solutions specializes in delivering 5-axis CNC Machining Services in PA. to industries requiring uncompromising accuracy and reliability. Our expertise supports a range of sectors where complex geometries and extreme conditions demand advanced machining capabilities.

Industries and applications that benefit from our 5-axis machining include:

Oil and Gas:

- Precision components for drilling equipment

- Pressure-resistant parts are designed to withstand harsh environments, including high temperatures and corrosive materials

- Complex valve components and flow control systems for accurate fluid and gas management

- Custom machined parts for oilfield tools, tailored to meet the unique demands of exploration and extraction

Energy Sector:

- High-precision turbine components for power generation

- Custom parts for renewable energy technologies, such as wind and solar systems

Electronics and Semiconductors:

- Precision-machined components for sensitive electronic assemblies

- Parts with tight tolerances for semiconductor manufacturing equipment

Aerospace and Defense:

- Lightweight, high-strength components for aircraft and defense systems

- Complex geometries are required for mission-critical applications

Medical Device Manufacturing:

- Intricate parts for surgical instruments and diagnostic equipment

- Components that meet stringent regulatory standards

Our team has completed many challenging projects across these industries. We leverage our decades of experience to deliver exceptional results and innovative solutions.

Quote for 5-Axis CNC Machining Services in PA

5-axis CNC machining enables the creation of complex components that would otherwise be impossible with conventional methods. This technology saves time and money by eliminating multiple setups and optimizing material usage. King Precision Solutions brings decades of experience and state-of-the-art equipment to every manufacturing challenge. We specialize in tackling projects other shops consider too difficult. Our meticulous attention to detail and strict quality control standards ensure each component we machine meets your exact specifications.

Contact us today at (877) 312-3858 to schedule a time to stop by our shop at 2200 Colonial Ave., Erie, PA 16506, to learn more about our 5-axis CNC machining services.

Click below to learn more and upload your relevant project files.